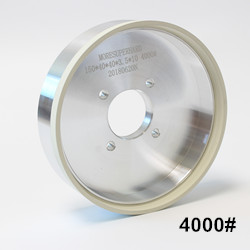

Peripheral diamond grinding wheel

Peripheral Diamond Grinding wheels for indexable inserts, must be of a high level of geometrical accuracy, with ability of significant material removal. We are able to produce various types wheels to suit all popular machines, such as WENDT, WAIDA, AGATHON, EWAG, COBORN, etc.

Advantages Of Peripheral Diamond Wheels

* High durability, long life

* Good edge quality of inserts

* Good surface accuracy retention

* High stock removal efficiency

Application Of Peripheral Grinding Wheels

Mainly used for precise edge grinding of indexable inserts, tungsten carbide inserts, ceramic inserts, CBN inserts.

Materials of workpiece: tungsten carbide, ceramics, PCD/ PCBN inserts, etc.

Applicable Machines:

400 Series: 400 PENTA, 400COMBI, 400SEMI, 400PERI.

350 Series: 350T B, 350COMBI

250 Series: PA250

WENDT:

400 Series: WAC715, WAC735

350 Series: WAM336

WAIDA

AP460E

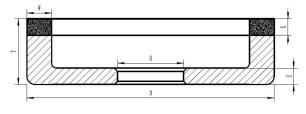

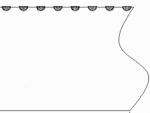

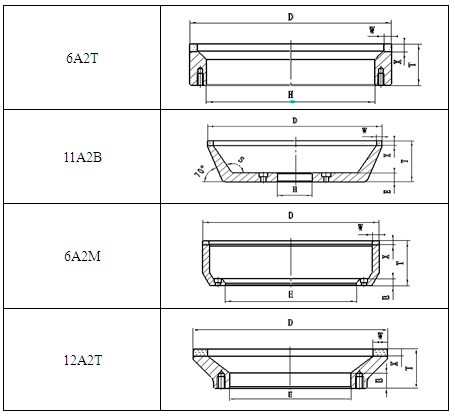

Models And Profile Drawings Of Peripheral Diamond Wheels:

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com