Stainless steel material, as the name suggests, is a steel material that is not easy to rust. Ferritic stainless steel is the most common type of stainless steel material, and it is a stainless steel with ferrite structure as the main structure in use. The chromium content of this stainless steel is between 11% and 30%. In addition, it also contains a small amount of molybdenum, titanium, niobium and other elements.

The difficulty of stainless steel processing is mainly reflected in these aspects:

1. Cutting tool material selection

Due to the high cutting force and high cutting temperature of stainless steel parts, cubic hydrogenated turning inserts with hardness second only to diamond and high temperature resistance can be used. In addition, its chemical inertia is very large, and iron group metals have no chemical action at 1200~1300 °C, which is very suitable for processing stainless steel materials.

2. When sharpening the rake face, the roughness value should be small

In order to avoid chip jamming, the front and rear surfaces of the tool should be carefully ground to ensure a small roughness value, thereby reducing chip flow resistance and avoiding chip jamming.

3. Keep the cutting tool edge sharp

The cutting edge of the knife should be kept sharp to reduce work hardening. The infeed and reverse infeed should not be too small, so as not to cut the tool in the hardened layer and affect the service life of the tool.

4. Cutting tool geometric parameters

The geometrical parameters of the tool have an important influence on its cutting performance. In order to make the cutting of cemented carbide tools light and smooth, a larger rake angle should be used to improve tool life. This is conducive to strengthening the cutting edge and giving full play to the advantages of the high compressive strength of ceramic tools. The size of the relief angle directly affects the wear and edge strength of the tool. The change of the entering angle will affect the change of radial cutting force and axial cutting force, as well as the change of cutting width and cutting thickness.

5. Pay attention to the grinding of the chip breaker

Due to the strong toughness of stainless steel chips, the chip flute on the rake face of the tool should be properly ground to facilitate chip breaking, chip holding and chip removal during the cutting process.

6. Choose the right cutting oil

Since stainless steel is prone to cohesion and poor heat dissipation, it is very important to choose a cutting oil with good anti-cohesion and heat dissipation during the cutting process, such as Yida Borun special stainless steel cutting oil, which has good cooling, cleaning, Anti-rust and lubricious.

7. Selection of cutting parameters

According to the characteristics of stainless steel materials, low speed and high feed should be selected when cutting. Using the above-mentioned process can overcome the difficulty of stainless steel processing, greatly improve the tool life of stainless steel in the cutting process, reduce the number of tool replacements in operation, and achieve satisfactory results in improving production efficiency and cutting accuracy, reducing cloth, etc. Labor intensity and overall production cost.

Stainless steel parts processing technology

Through the analysis of the above processing difficulties, the processing technology of stainless steel and the design of related tool parameters should be quite different from those of ordinary structural steel materials. The specific processing technology is as follows:

1. Drilling

During drilling, due to the poor thermal conductivity and small elastic modulus of stainless steel, it is difficult to process holes. To solve the problem of hole processing of such materials, it is mainly to select the appropriate tool material, determine the reasonable geometric parameters of the tool and the cutting amount of the tool. When drilling the above materials, the drill bits should generally be made of W6Mo5Cr4V2AI, W2Mo9Cr4Co8 and other materials. However, when the commonly used W18Cr4V ordinary standard high-speed steel drill bit is used for drilling, due to the shortcomings of small apex angle, too wide chips, it cannot be discharged out of the hole in time, and the cutting fluid cannot cool the drill bit in time, and the stainless steel material has poor thermal conductivity, resulting in concentration. When the cutting temperature on the cutting edge rises, it is easy to cause burns and chipping of the two flanks and the main edge, which reduces the service life of the drill bit.

1) Tool geometric parameter design When drilling with W18CrV junction, the cutting force and cutting temperature are concentrated on the drill tip. In order to improve the durability of the cutting part of the drill bit, the apex angle can be appropriately increased. The apex angle is generally selected as 135° ~140. The increase of the apex angle will also reduce the rake angle of the outer edge and narrow the cuttings to facilitate chip removal. However, after increasing the apex angle, the chisel edge of the drill bit becomes wider, resulting in an increase in cutting resistance. Therefore, the chisel edge of the drill bit must be ground. After grinding, the bevel angle of the chisel edge is 47~55°, and the chisel edge rake angle is 3° ~5°, when grinding the chisel edge, the corner between the cutting edge and the cylindrical surface should be ground into rounded corners to increase the strength of the chisel edge. Due to the small elastic modulus of the stainless steel material, the elastic recovery of the metal under the chip layer is large, and the work hardening is serious during the processing. If the relief angle is too small, the wear of the flank of the drill bit will be accelerated, and the cutting temperature will be increased, which will reduce the life of the drill bit. Therefore, the relief angle must be increased appropriately, but if the relief angle is too large, the main edge of the drill will become thinner and reduce the rigidity of the main edge, so the relief angle should be 12° ~ 15°. In order to narrow the drill chips and facilitate chip removal, it is also necessary to open staggered chip splitters on the two flanks of the drill bit.

2) Cutting amount selection When drilling, the choice of cutting amount should start from the basic point of reducing the cutting temperature, because high-speed cutting will increase the cutting temperature, and high cutting temperature will aggravate tool wear, so the cutting amount is the most important is the choice of cutting speed. Generally, the cutting speed is 12 ~ 15m/min more appropriate. The feed rate has little effect on the tool life, but if the feed rate is too small, the tool will cut in the hardened layer and aggravate the wear; if the feed rate is too large, the surface roughness will be deteriorated. Combining the above two factors, it is advisable to choose the feed rate as 0.32 ~ 0.50mm/r.

2. Reaming processing

1) Tool geometric parameter design Most of the reaming of stainless steel materials use carbide reamers. The structure and geometric parameters of reamers are different from ordinary reamers. In order to enhance the strength of the cutter teeth and prevent chip clogging during reaming, the number of reamer teeth is generally relatively small. The rake angle of the reamer is generally 8° ~ 12°, but in some specific cases, in order to achieve high-speed reaming, the rake angle of 0° ~ 5° can also be used; the back angle is generally 8° ~ 12°; the main declination angle The choice of the hole varies depending on the hole. Generally, the through hole is 15° ~ 30°, and the non-through hole is 45°; when reaming, in order to make the chips discharge forward, the blade inclination angle can also be increased appropriately, and the blade inclination angle - - generally 10° ~ 20°; the margin width is 0.1 ~ 0.15mm; the upper inverted cone of the reamer should be larger than the ordinary reamer, the carbide reamer is generally 0.25 ~ 0.5mm/100mm, and the high speed steel reamer is 0.1 ~ 0.25mm/100mm; the length of the corrected part of the reamer is generally 65% ~ 80% of the ordinary reamer, and the length of the cylindrical part is 40% ~ 50% of the ordinary reamer.

2) The cutting amount is selected when reaming, the feed rate is 0.08 ~ 0.4mm/r, the cutting speed is 10 ~ 20m/min, the rough reaming allowance is generally 0.2 ~ 0.3mm, and the fine reaming allowance is 0.1 ~ 0.2mm. Carbide cutters should be used for rough reaming, and high-speed steel cutters can be used for fine reaming.

3) When the cutting fluid is made of stainless steel for reaming, the total loss system oil or molybdenum disulfide can be used as the cooling medium.

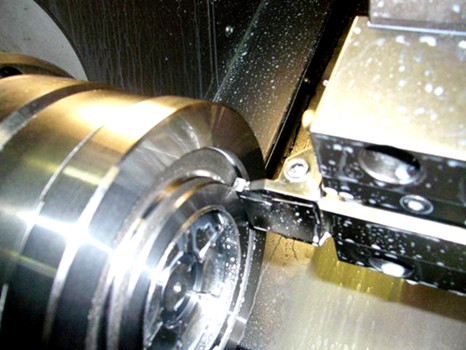

3. Boring processing

1) Tool material selection Due to the high cutting force and high cutting temperature when processing stainless steel parts, the tool material should try to choose YW or YG cemented carbide with high strength and good thermal conductivity. YT14 and YT15 carbide inserts can also be used for finishing. When processing parts of the above materials in batches, ceramic material cutting tools can be used. Since the main characteristics of this type of material are high toughness and severe work hardening, the chips for cutting these materials are generated in the form of unit chips, which will cause the tool to vibrate and easily cause the blade to be micro. Therefore, the first thing to consider when choosing ceramic tools to cut parts of such materials is microscopic toughness. At present, Sialon is a better choice, especially the a/β Sialon material, which attracts attention because of its excellent high-temperature deformation resistance and diffusion wear performance, and has been successfully applied to cutting nickel-based alloys, and its service life is far More than Al2O3 based ceramics. In addition, SiC whisker-reinforced ceramics are also a very effective tool material for cutting stainless steel or nickel-based alloys.

For the processing of quenched parts of such materials, CBN (cubic boron nitride) blades can be used. The hardness of CBN is second only to diamond, and the hardness can reach 7000 ~ 8000HV, so the wear resistance is very high. Compared with diamond, the outstanding advantages of CBN are: The heat resistance is much higher than that of diamond, up to 1200°C, and can withstand very high cutting temperatures. In addition, its chemical inertness is very large, and it has no chemical effect with iron group metals at 1200 ~ 1300 ° C, so it is very suitable for processing stainless steel materials. Its tool life is dozens of times that of cemented carbide or ceramic tools.

2) Tool geometric parameter design The tool geometric parameter plays an important role in its cutting performance. In order to make the cutting light and smooth, the carbide tool should adopt a larger rake angle to improve the tool life. Generally, the rake angle is 10°~20° for rough machining, 15°~20° for semi-finishing, and 20°~30° for finishing. The basis for selecting the main deflection angle is that when the rigidity of the process system is good, it can be 30°~45°; if the rigidity of the process system is poor, it can be 60~75°; when the ratio of the length to the diameter of the workpiece exceeds 10 times, it can be 90° °.

When boring stainless steel materials with ceramic tools, in most cases, ceramic tools are cut with a negative rake angle. Generally, the size of the front angle should be 5°, which is conducive to strengthening the knife work and giving full play to the superiority of the high compressive strength of ceramic tools. The size of the back angle directly affects the wear of the tool and also affects the strength of the knife. Generally, 5°~12 °. The change of the main deflection angle will affect the changes of the radial cutting force and axial cutting force, as well as the cutting width and cutting thickness. Because the vibration of the process system is extremely unfavorable to the ceramic tool, the choice of the main deflection angle should help reduce this vibration, and one should choose 30°-75°. When CBN is selected as the tool material, the geometric parameters of the tool are rake angle 0° ~ 10°, relief angle 120° ~ 20°, and entering angle 45° ~ 90°.

3) When sharpening the rake face, the roughness value should be small. In order to avoid the phenomenon of chips sticking to the knife, the front and flank faces of the tool should be sharpened carefully to ensure a small roughness value, thereby reducing the chip outflow resistance and avoiding chip sticky knife.

4) The cutting edge of the tool should be kept sharp. The cutting edge of the tool should be kept sharp to reduce work hardening. The feed rate and back cutting amount should not be too small to prevent the tool from cutting in the hardened layer and affect the service life of the tool.

5) Pay attention to the grinding of the chip breaker. Due to the strong and tough characteristics of stainless steel chips, the grinding of the chip breaker on the rake face of the J tool should be appropriate, so that chip breaking, chip containment, and chip removal are convenient during the cutting process.

6) The selection of cutting amount is based on the characteristics of stainless steel materials, and it is advisable to choose low speed and large feed rate for cutting during processing.

When using ceramic tools for boring, the reasonable selection of cutting amount is one of the keys to give full play to the performance of ceramic tools. For continuous cutting of ceramic tools, the cutting amount can be selected according to the relationship between wear durability and cutting amount; for intermittent cutting, the reasonable cutting amount should be determined according to the law of tool damage. Due to the superior heat resistance and wear resistance of ceramic knives, the impact of cutting amount on tool wear life is smaller than that of cemented carbide tools. In general, when machining with ceramic tools, the feed rate is most sensitive to the damage of the tool. Therefore, according to the nature of the workpiece material, on the premise that the power of the machine tool, the rigidity of the process system and the strength of the blade are allowed, when boring stainless steel parts, choose a high cutting speed, a large amount of back cutting and a relatively small cutting edge. Give the amount.