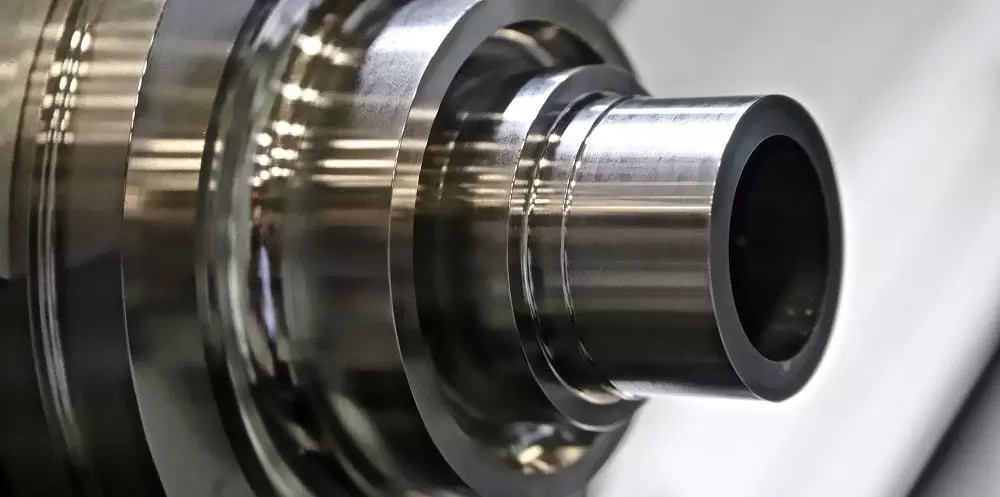

Many shapes, sizes and types of bearings exist including: ball bearings, roller bearings, needle bearings, and tapered roller bearings

OUTER RING

The outer part of a bearing that fi ts into the housing and contains the internal raceway for the rolling elements.

INNER RING

The inner part of a bearing that fi ts on a shaft and contains the external raceway for the rolling elements.

RACEWAY

The ball or roller path, profi led in the inner and outer rings in which the balls or rollers ride. Also called: guide path, race, ball path, roller path.

EXTERNAL RACEWAY

The ball or roller path on an inner ring. Also called: inner race, inner ring race.

INTERNAL RACEWAY

The ball or roller path on the bore of the outer ring. Also called: outer ring race, outer race.

BALL

A spherical rolling element.

ROLLER

Cylindrical or conical rolling element of slightly greater length than diameter.

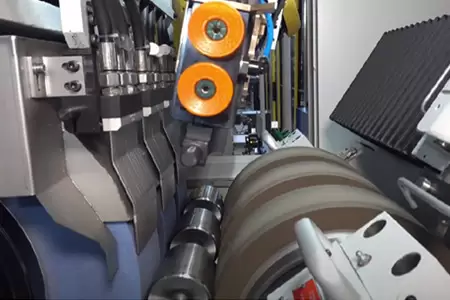

Cylindrical grinding and the step face.

2. The grinding method of the cylinder and the step surface

1. The method of cylindrical grinding

(1) Longitudinal grinding method

Longitudinal grinding method is the most commonly used grinding method. During grinding, the table is used for longitudinal reciprocating feed, and the grinding wheel is used for periodic transverse feed. The grinding allowance of the workpiece should be ground in multiple reciprocating trips.

Characteristics of longitudinal grinding method (referred to as longitudinal method) :

1) In the whole width of the grinding wheel, the abrasive works differently. The sharp Angle of the left (or right) end face of the grinding wheel mainly plays the cutting role. Part of the grinding allowance of the workpiece is removed by the abrasive particles at the sharp Angle of the grinding wheel, while most of the abrasive particles at the width of the grinding wheel play the role of reducing the surface roughness of the workpiece. The longitudinal grinding method has low grinding force, good heat dissipation condition, and can obtain higher machining accuracy and smaller surface roughness.

2) Low labor productivity.

3) Low grinding force, suitable for grinding slender, precision or thin wall workpiece.

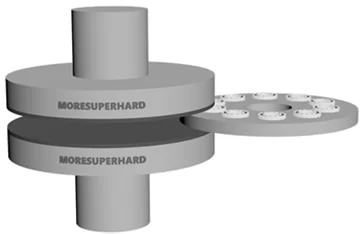

(2)Plunge grinding method

The length of the cylinder of the grinding workpiece shall be less than the width of the grinding wheel, and the grinding wheel shall make continuous or intermittent transverse feed movement until all the allowance is removed. There is no longitudinal feed movement of the grinding wheel. Higher cutting speed can be used in coarse grinding; In fine grinding, the cutting speed is low to prevent the workpiece from burning and heating deformation.

The characteristics of cutting in grinding method (referred to as cutting in method) :

1) The working condition of the grains on the whole width of the grinding wheel is the same, giving full play to the grinding effect of all the grains. At the same time, because of the continuous transverse feed, the basic grinding time is shortened, so the production efficiency is very high.

2) The radial grinding force is large, the workpiece is easy to produce bending deformation, generally not suitable for grinding fine workpiece.

3) Large grinding heat is generated during grinding, and the workpiece is easy to burn and heat deformation.

4) The shape of the grinding wheel surface (dressing traces) will be copied to the workpiece surface and affect the surface roughness of the workpiece. In order to eliminate the above defects, small longitudinal movement can be made at the end of the cutting method.

5) Due to the limitation of the width of the grinding wheel, the cutting method is only suitable for grinding the outer circular surface with short length.

(3) Step grinding method

Subsection grinding method is also called comprehensive grinding method. It is the comprehensive application of the cutting method and the longitudinal method, that is, the first use the cutting method to coarse grinding workpiece segments, leaving 0.03~0.04mm allowance, and finally use the longitudinal method to fine grinding to size. This grinding method not only takes advantage of the high efficiency of the cutting method, but also has the advantage of the high precision of the longitudinal method. In segmental grinding, there should be 5~10mm overlap between two adjacent sections. This grinding method is suitable for grinding the workpiece with good allowance and rigidity, and the length of the workpiece should be appropriate. Considering the grinding efficiency, wider grinding wheels should be used to reduce the number of segments. When the length of the machined surface is about 2~3 times of the width of the grinding wheel, it is the best condition.

(4) Deep grinding method

This is a more commonly used grinding method, which uses a large back bite to grind all the grinding allowance of the workpiece in a single longitudinal feed. Because the basic grinding time is shortened, the labor productivity is high.

Characteristics of deep grinding method:

1) Suitable for grinding rigid workpiece

2) Grinder should have high power and stiffness

2. Grinding method of step surface

The step surface of the workpiece can be ground out by the end face of the grinding wheel by moving the table by hand after grinding the outer circle. During grinding, the grinding wheel should be slightly removed laterally and the work table should be manually operated until the grinding wheel is in contact with the end face of the workpiece, and the grinding wheel should be fed intermittently. Pay attention to pouring sufficient cutting fluid to avoid burning the workpiece. Usually, the end face of the grinding wheel can be shaped into a concave shape to reduce the contact area between the grinding wheel and the workpiece and improve the grinding quality.

When grinding the step surface, the grinding wheel is under great lateral pressure. Therefore, it is necessary to move the table carefully during operation. When the end face of the workpiece contacts with the grinding wheel, the longitudinal feed handwheel can be gently tapped by hand to achieve small and uniform feed.

3. Selection of outer round grinding wheel

1. Principle of reasonable selection of grinding wheel

The choice of grinding wheel not only affects the machining accuracy and surface quality of the workpiece, but also affects the loss, service life, production efficiency and production cost of the grinding wheel. To achieve the purpose of reasonable selection of grinding wheel, the following basic principles should be observed:

(1) The abrasive particles shall have good grinding performance.

(2) The grinding wheel should have proper “self-sharpening” during grinding.

(3) The grinding wheel should not be blunt and has a long service life.

(4) Small grinding force is generated during grinding.

(5) Small grinding heat is generated during grinding.

(6) can achieve high machining accuracy (dimensional accuracy, shape accuracy, position accuracy).

(7) Small surface roughness can be achieved.

(8) The workpiece surface does not produce burns and cracks.