Electroplated Diamond Band Saw Blades

The diamond blades are available in continuous and gulleted edges. In the processing of the electroplated diamond band saw,the heating temperature of the diamond is less than 100ºC,so the damage to the diamond is very small,then the Electroplated Diamond Band Saw can also have the good long life time.

Application of diamond band saw blade

Cutting super hard material and brittle material ,such as monocrystalline silicon,polycrystalline silicon in solar energy, semiconductor and sapphire, ruby in LED field, quartz glass, silicon ingot, sapphire ingot and so on.

The specifications of diamond band saw blades

| Length(mm) | width(mm) | thickness(mm) |  |

| 3230 | 40 | 0.7 | |

| 3440 | 40 | 0.7 | |

| 3530 | 40 | 0.7 | |

| 3700 | 80 | 0.6 , 0.7 | |

| 4320 | 60 | 0.5 , 0.6 , 0.7 | |

| 5400 | 60 | 0.5 , 0.6 , 0.7 | |

| 6095 | 40 | 0.7 | |

| other specifications can be made according to customers requirements | |||

Edge shapes of diamond band saw blades:

|

Continuous

A variety of band core width available

Continuous rim design reduces the saw marks on the materials

Suitable for dry cutting hard materials , such as glass , ceramic , carbon materials and so on.

|

|

segmented ( half moon):

Cutting hard and brittle materials

Superior tool life and cutting ability in silicon processing

Allows greater flexibility in customizing blade edge width and pitch

|

|

Serrated :Wide width band saw blades possible

Cutting difficult to cut materials

Reduced -loading saw tooth design encourages chip evacuation

|

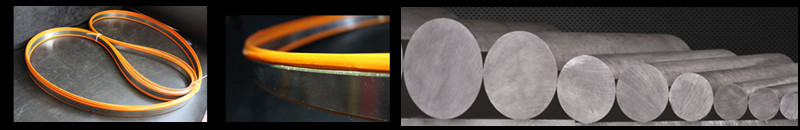

Application Cases Of Continuous Diamond Coated Band Saw Blade:

* 6400mm length Continuous Diamond Coated Band Saw Blade Have Sent To Indian Clients

| product name | Continuous Diamond Coated Band Saw Blade |

| size | 6400mmx41mmx1.2mm |

| applicable workpiece | cutting Graphite Materials |

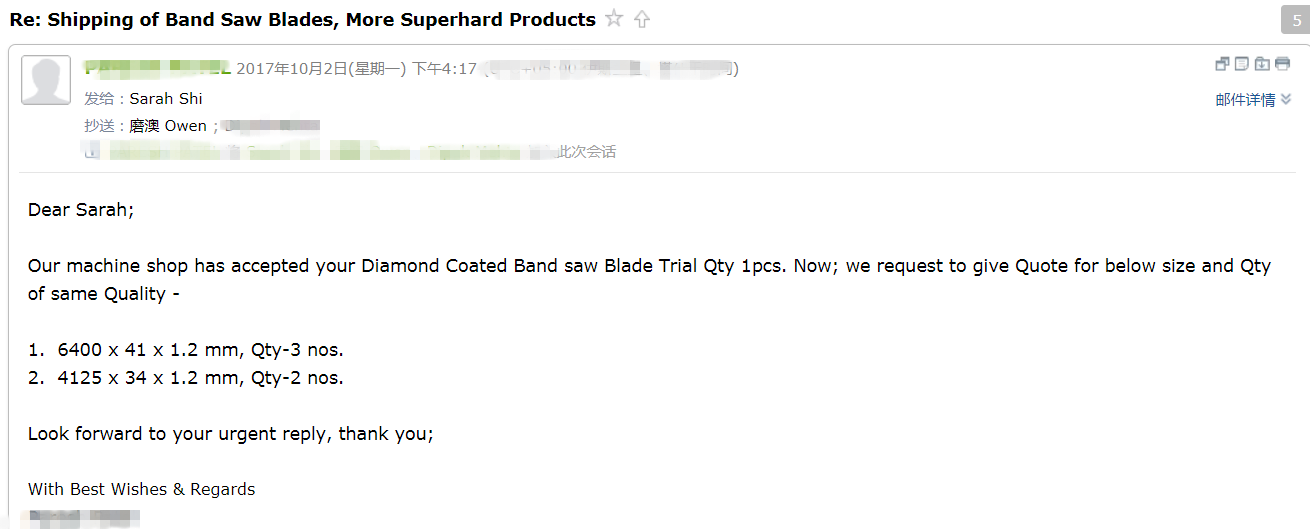

| |

customer feedback

| |