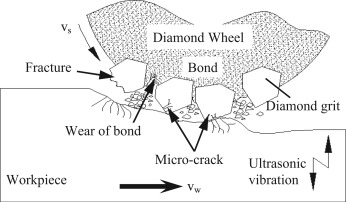

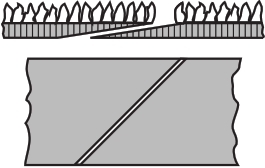

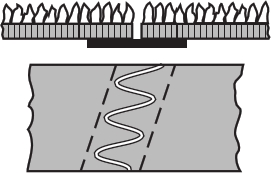

Under the condition of low grinding force and grinding speed, after the operation of diamond grinding wheel, the surface of the diamond abrasive is scattered with many edges clearly reflecting the small wear plane of diamond abrasive. This is because the mechanical wear caused by the mechanical conflict between diamond abrasive particles and superhard data is gradually carried out, and the wear amount of abrasive particles is directly proportional to the grinding stroke length.

According to the properties of diamond, the degree of graphitization depends on the crystal integrity of diamond abrasives, and the degree of graphitization is related to the crystal orientation. Diamond abrasives with good crystal integrity have a low degree of graphitization loss.

On the surface of diamond grinding wheel, some diamond abrasive grains crack and break, causing the whole grain to fall off. Because crystal cleavage is the plane rupture caused by the type strength and distribution of chemical bond of crystal structure element 7, it often occurs along the directional plane at the end of the strength of chemical bond.

The fracture formed by the breakage is that in the irregular grinding process, the abrasive rises to high temperature instantaneously, and then cools rapidly under the effect of grinding fluid, which is repeated repeatedly, forming a great thermal stress on the surface of the abrasive, which makes the surface of the abrasive crack, the thermal stress, the fracture wear and the defect distribution and oxidation of the diamond abrasive Graphitization has a close contact, so, first of all, some thermal stress occurs at the surface shortcomings of the abrasive crystal, causing multiple cracks to occur and expand under the effect of grinding force, some of the weakest strength of the crushing and falling abrasive is the result of grinding force and grinding heat together.

Reasonable selection of diamond abrasive and bond:

Selection of abrasive particle size

The selection of abrasive particle size of diamond grinding wheel directly affects the surface quality and processing power of superhard data grinding. On the premise that the processing quality requirements can be satisfied, the coarser particle size should be selected as far as possible to improve the processing power Abrasive with 120-150# particle size can be selected for coarse grinding, abrasive with 180-240# particle size can be selected for fine grinding, and micro-powder abrasive with W40-W7 particle size can be selected for superfine grinding

Selection of abrasive concentration

The concentration of abrasive in diamond grinding wheel has certain influence on the grinding effect of superhard data, too high or too low concentration will cause the premature drop of abrasive, so that the grinding wheel loss cost addition test results show that in coarse grinding, a higher concentration can be selected to add the number of useful abrasive particles per unit area, and in improving the processing power + fine grinding, a lower concentration should be selected Under normal conditions, abrasive concentration can be selected 100-150% when coarse grinding, abrasive concentration can be selected 75-100% when fine grinding.

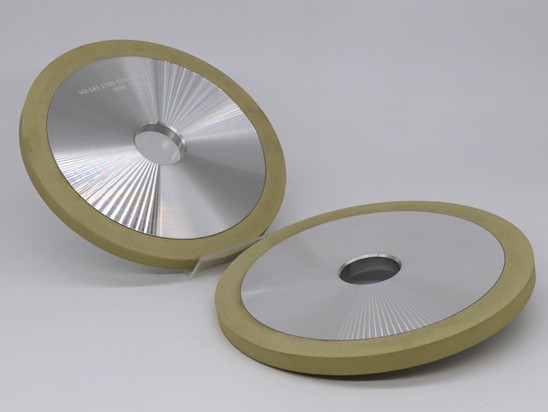

Selection of binding agent

Metal bonds with excellent thermal conductivity (mainly bronze grinding wheels) have a larger binding force on abrasive grains, which is suitable for diamond abrasives with intact crystal shape and relatively high grinding ratio. Resin bond is suitable for diamond abrasives with high brittleness and low strength because of its weak adhesion to abrasive particles. The function of ceramic bond is between the above two. The binding force of cast iron short fiber bond on abrasive particles is as high as 50-100kg/mm2, and the tensile strength is as high as 15-30kg/mm2, which is much superior to the function of common metal bonds. The grinding ratio of the diamond grinding wheel made of the diamond grinding wheel is about 4-5 times that of the resin bond grinding wheel, which is suitable for the manufacture of diamond grinding wheel with intact crystal shape.

Under the condition of low grinding force and grinding speed, mechanical conflict wear occurs mainly in diamond abrasive particles. Under the condition of high temperature in the grinding zone, the diamond particles oxidize and graphitize. The cleavage and crushing of abrasive particles are the result of the combined effect of grinding force and grinding heat. When the mechanical force on the grinding grains exceeds the binding force of the grinding wheel bond, the whole grains fall off.

Welcome to contact us:

Email:doris@moresuperhard.com

Know details:

.jpg)