CBN Grinding Wheel For Internal Grinding

The Features Of CBN Grinding Wheel For Internal Grinding

High efficiency, High workpiece precision, Good workpiece consistency, Long life time .

Application Of CBN Grinding Wheel For Internal Grinding

Grinding of Con-rods ends in the Auto Industry .

Grinding of Hydraulic and Pneumatic Cylinders .

CVJ ball-cage, inner and outer raceway .

Hydraulic tappet of automobile motor .

Grinding of Bores of Inner Rings .

Grinding of Gears Bores, Collects.

Pump stator of automobile,Grinding of Gun Barrels .

Roller, cylinder, flange cover of air-condition compressor.

Grinding of Inner and outer faces of Ball & Roller Bearings .

Specification Of CBN Grinding Wheel For Internal Grinding

| Model | Diameter (mm) | Bore Diameter (mm) | Height (mm) |

| 1A8 | 4 | 1.5 | 5 |

| 1A8 | 6 | 2 | 8 |

| 1A8 | 12 | 4 | 8 |

| 1A8 | 20 | 6 , 8 | 10 |

| 1A8 | 25 | 8 , 13 | 20 |

| 1A8 | 30 | 10 | 15 |

| 1A8 | 35 | 12 , 15 | 12 |

| 1A8 | 40 | 15 | 15 |

| 1A8 | 40 | 15 | 25 |

| 1A8 | 45 | 30 | 50 |

| 1A1W | 17.5 | 11 | 5.5 |

| other size can be made according to customers requirements. | |||

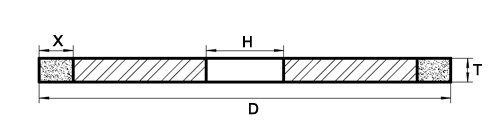

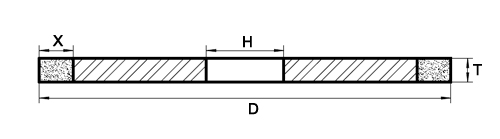

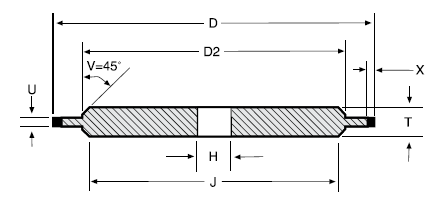

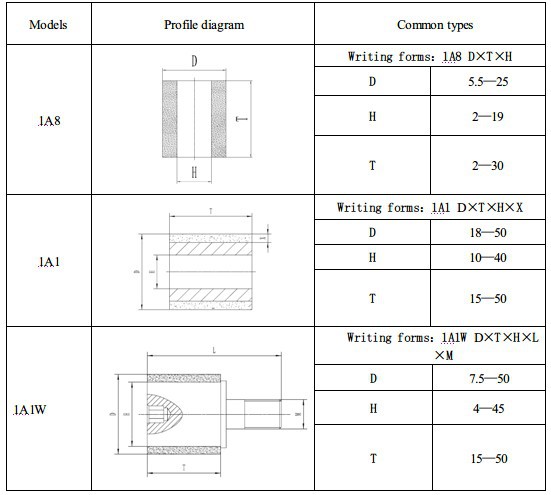

Models And Profile Sketches Of CBN Grinding Wheel For Internal Grinding

The Cases Of CBN Grinding Wheel For Internal Grinding

1A1W vitrified CBN internal grinding wheel for hydraulic industry

Diamond / CBN Vitrified Bond Internal Grinding Wheels (1A1, 1A8, 1A1W, 1B1) .

We can also produce grinding wheel mounted points/ grinding head special for air condition compressor.

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2.Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

Products Range:

1. vitrified bond/resin bond/Metal bond/Electroplated diamond grinding wheel & other diamond tools

2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts

3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools

4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers

5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits

6. PCD tool grinder & PCD grinding machine

2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts

3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools

4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers

5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits

6. PCD tool grinder & PCD grinding machine

Our product’s advantages:

1.High grinding efficiency

|

2.Wonderful edge quality

|

3.Long service life

|

4.High polishing efficiency

|

5.Large Exports

|

6.Considerable after-sell service

|

7.Amazing performance

|

8.Various types and sizes available

|

9.Direct Factory Manufacturer

|

10.Backing/substrate material: Aluminum

|

11.Abrasive layer: diamond

|

12.Bond: vitrified

|

13.Excellent cutting edges

|

14.Reduced cycle times

|

15.Custom Engineered

|

Packaging and shipping

Packing

|

Carton, plastic bag,or as your request

|

Shipping

|

we use DHL,UPS,FEDEX,ect.to ship the goods,or according to the customer's requirement

|

Delivery time

|

about3-7days, for special time according to your quantity

|

Our services

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or designs.

FAQ:

Q1. Can negotiate the price?

A: yes, you can. We will give some discount according to your quantity.

Q2. How can now my order’s production progress?

A: we will keep closely track the production and shipment progress. And we will inform you with the newest progress about producing and shipping.

Q3. How can you ensure your quality?

A: We have pass the ISO 9001:2008. If there is any problem with our products, please send me the detailed picture of the problem, once we verify it, we will change the products for you within 30 days.

Q4: When I contact you is suitable?

You can contact Us at any time, we promise that we will reply you within 12 hours.

A:So, please contact me for more information about our product, service and related issues.

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com