Vitrified diamond grinding wheels for PDC

Vitrified products have the features of sharp cutting, high efficiency, long life ,easy dressing. Vitrified diamond wheels are used for rough and precision grinding the Cylinder of Polycrystalline Diamond Compacts (PDC cutter).

Application Of Vitrified Diamond Grinding Wheels For PDC

Grinding PCD, PCBN,tungsten carbide, ceramic, cermet, etc.

Advantages Of Vitrified Diamond Grinding Wheels For PDC

* Compared with resin diamond grinding wheel, vitrified bond wheels lead to 35% grinding cost reduced, 40% grinding time of each PDC saved, and the size precision of PDC improved (from ±0.03mm to ±0.01mm)

* Good surface finish after grinding and high efficiency

* Less dressing time, long service life and stable quality

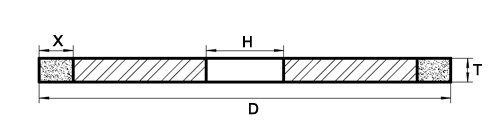

Specifications Of vitrified diamond wheels For Rough And Precision Grinding PDC

rough grinding PDC cutter

| Model | D (mm) | T (mm) | H (mm) | X (mm) |

1A1

| 200 | 50 | 75 | 10 |

| 250 | 50 | 75 | 10 | |

| 300 | 50 | 127 | 10 | |

| 350 | 50 | 127 | 10 | |

| 400 | 50 | 203 | 10 | |

| 450 | 50 | 228.6 | 10 | |

| 500 | 50 | 305 | 10 | |

| Others Size Can Be Made According To Customer’s Requirements. | ||||

Precision grinding PDC cutter

| Model | D (mm) | T (mm) | H (mm) | X (mm) |

| 1A1, 6A1, 9A1 | 200 | 50 | 75 | 10 |

| 250 | 100 | 75 | 10 | |

| 300 | 100,150 | 127 | 10 | |

| 350 | 125, 150 | 127 | 10 | |

| 400 | 150,300 | 203 | 10 | |

| 450 | 150,200,300 | 228.6 | 10 | |

| 500 | 150,200 | 305 | 10 | |

| Others Size Can Be Made According To Customer’s Requirements. | ||||

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com

没有评论:

发表评论