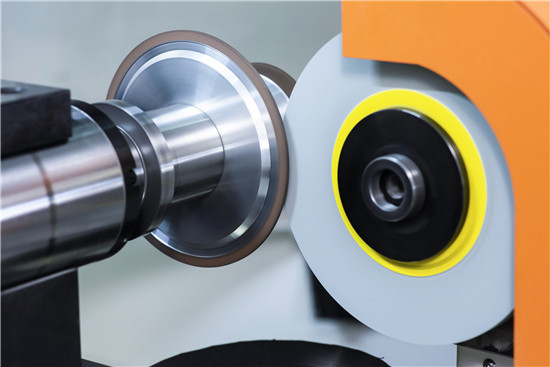

How to dress diamond grinding wheel?

In the dressing process, the ordinary abrasive grinding wheel is aligned with the diamond grinding wheel, and the diamond grinding wheel rotates, while the ordinary abrasive grinding wheel carries out feed movement while rotating Under the action of friction, the grinding particles on the surface of the diamond grinding wheel begin to rotate slowly, which produces certain extrusion pressure on the metal adhesive while rotating, leading to cracks in the adhesive. With the continuous action of friction, cracks in the adhesive are further expanded Finally, the adhesive breaks, making the blunt diamond particles fall off the surface of the grinding wheel and exposing the sharp diamond particles for the purpose of repair.

Q: What material is suitable for grinding artificial diamond wheel?

A: synthetic diamond grinding wheel is suitable for grinding high hardness inorganic materials Cemented carbide materials and high hardness of metal materials Diamond grinding wheel for grinding glass ceramic ferrite and semiconductor materials and other hard brittle materials and metal materials, and carbide materials Synthetic diamond grinding wheel is grinding carbide optical glass ceramic gem stone high hardness The best grinding tool for brittle non-metallic materials.

Q: What material is suitable for grinding artificial diamond wheel?

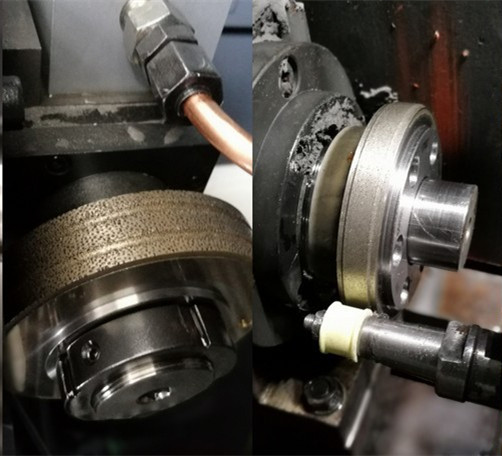

A: Diamond grinding wheel, with diamond abrasive as raw material, made of metal powder resin powder ceramics and electroplating metal circular through hole consolidation abrasive called diamond grinding wheel (alloy grinding wheel).

Diamond grinding wheel belongs to superhard grinding wheel. Compared with ordinary grinding wheel, diamond grinding wheel has very obvious characteristics and advantages:

1. The hardness of diamond abrasive determines the main characteristics of diamond grinding wheel: it can effectively grind hard alloy glass ceramics and other difficult materials, grinding tools have the longest service life.

2 Diamond has higher wear resistance, the less wear of grinding wheel, the longer the use time. In the grinding process, the size, shape and shape of diamond grinding particles change little, more suitable for high-precision machining, high production efficiency diamond wheel is a kind of tool that can meet the requirements of efficient and precision machining at the same time.

3. The repaired diamond grinding wheel can maintain the micro-blades of particles for a long time, and the good cutting performance ensures the small grinding force in the grinding process, thus reducing the grinding power and saving energy.

4. Diamond has good thermal conductivity, conducive to heat dissipation, avoid the phenomenon of workpiece burns, cracking and falling off, greatly improve the quality of workpiece surface processing.

Welcome to contact with us:

Email: info@moresuperhard.com

没有评论:

发表评论